Key Features of the HWF135 Automatic Rod Changing Horizontal Directional Drill

1. Automatic Rod Changing System:

One of the most innovative features of the HWF135 is its automatic rod changing system. This technology significantly reduces manual labor

and increases operational efficiency by automatically handling the rods during the drilling process. This feature not only saves time but also

enhances safety by minimizing the need for direct human intervention.

2. High Precision and Accuracy:

The HWF135 is equipped with advanced guidance systems that ensure high precision and accuracy in drilling operations. This is particularly

beneficial for projects that require exact directional drilling, such as pipeline installations or utility placement, where even minor deviations can

lead to significant issues.

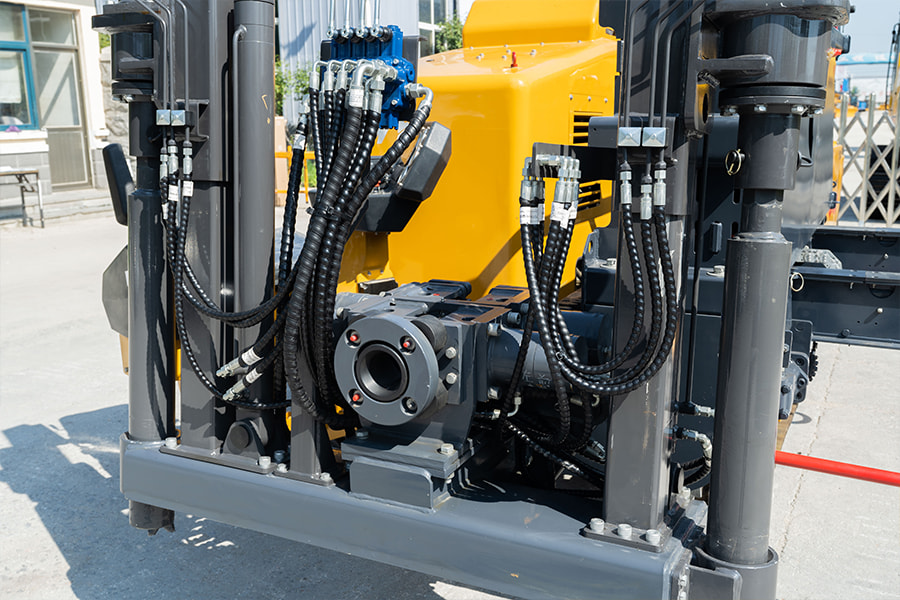

3. Powerful Drilling Capability:

With a robust engine and powerful torque, the HWF135 is capable of handling a wide range of soil types and challenging terrains. Its high-powered

drilling capabilities make it ideal for both soft soils and hard rock formations, ensuring versatility and adaptability across different projects.

4. User-Friendly Control System:

The HWF135 features an intuitive control system that allows operators to manage the drilling process with ease. The user-friendly interface provides

real-time feedback and monitoring, helping operators make informed decisions quickly. This feature reduces the learning curve and increases productivity on-site.

5. Durable Construction:

Built with high-quality materials and designed to withstand harsh working conditions, the HWF135 offers exceptional durability and longevity.

Its rugged construction ensures that it can perform reliably in demanding environments, reducing maintenance costs and downtime over the long term.

6. Environmentally Friendly Operation:

The HWF135 is designed with environmental considerations in mind. Its efficient fuel consumption and reduced emissions make it a more sustainable

option for drilling operations. This feature is particularly important for projects that prioritize environmental impact and regulatory compliance.

7. Enhanced Safety Features:

Safety is a paramount concern in any drilling operation, and the HWF135 addresses this with multiple built-in safety features. From automated

shut-offs to emergency stop mechanisms, this machine is designed to protect both operators and equipment, minimizing the risk of accidents and injuries.

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments